The ventilated and breathable roof is a concept that, technically is made system

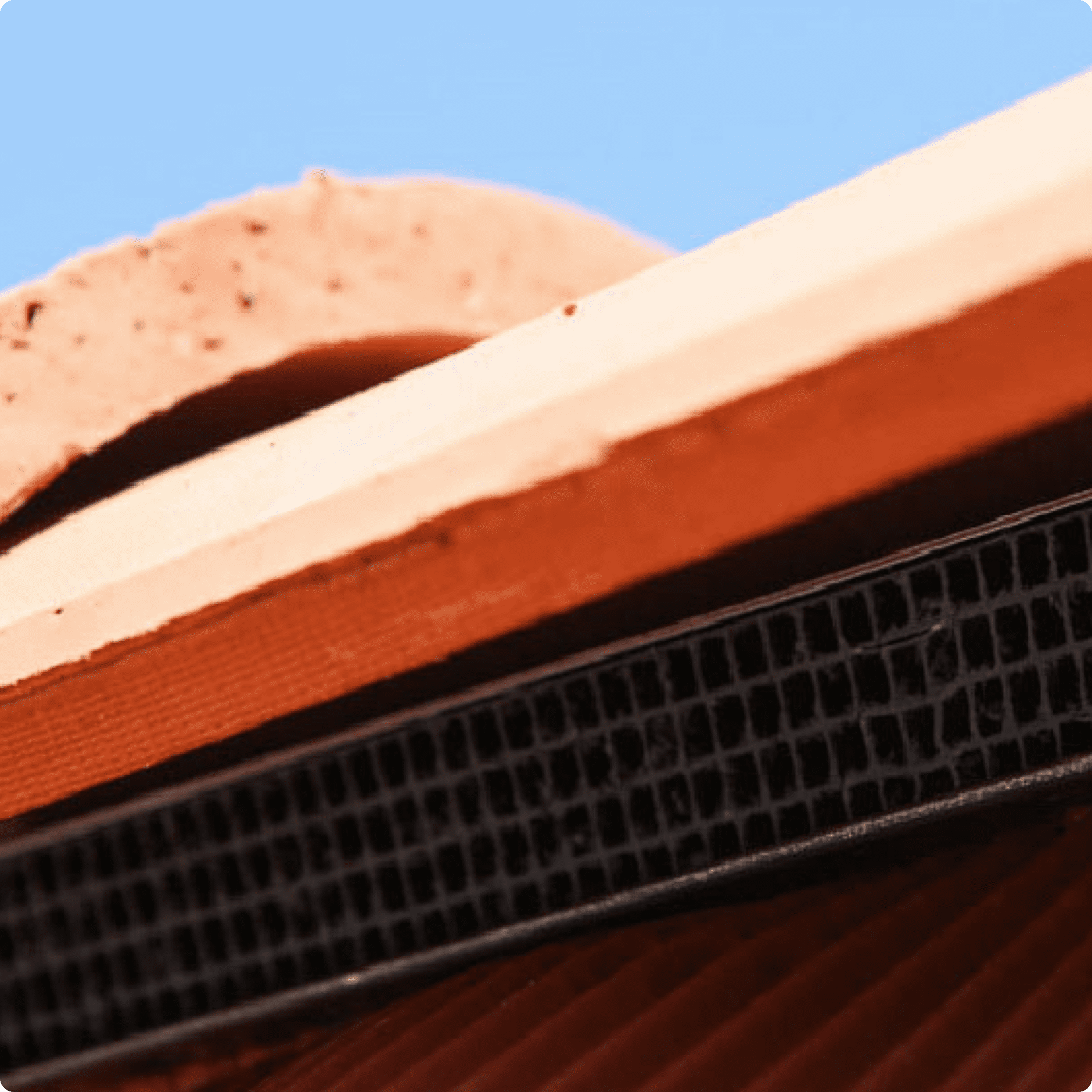

It is a roofing system that involves the dry laying of both tiles and embrici, with mechanical attachment, on a wooden structure and in which aspects related to safety, ventilation, breathability and insulation are enhanced. These qualities are ensured by the structural elements, insulating components, a mechanically anchored membrane, and a construction criterion that provides a single air chamber that allows roof ventilation and microventilation of the underlayment.

All materials are chosen from environmentally friendly ones (natural, recyclable, and recycled) that promote hygrothermal self-regulation of the roof, the attic environment, and a consequent greater and longer preservation of the structure. The real reason for preferring the ventilated and breathable roof to a conventional roof lies in the well-being of those living under it and the building.

The adoption of this system requires compliance with precise characteristics, which are not always easy to comply with.

Advantages

SAFETY

Mechanical anchoring of the roofing elements to the structure allows for installation without the aid of binders (mortars or foams), which could damage the roof over time. The anchorage made directly on batten, not tile on tile, ensures safe installation on any slope: from about 30 percent upwards. Such a system optimizes the stability of the roofing, its water tightness, its maintenance and allows its safe walkability.

BREATHABILITY

Wood was chosen as the structural element because of its breathable characteristics, hygrothermal regulator and pleasantness to the sight and touch. Together with the wood, the two breathable membranes, one dustproof and windproof, the other waterproof, preserve against accidental water infiltration without retaining vapor.

VENTILATION

The unique, carefully designed air chamber ensures roof ventilation and microventilation of the underlay. The resulting chimney effect promotes, through the ridge, the disposal of moisture and thus the healthiness of the roof covering, reduces maintenance costs, and increases the performance of the insulation, in accordance with the Implementing Regulations of Law 10/91.

INSULATION

The insulation panels are made of wood fiber, assembled by pressure with its own natural glue, lignin. The wood comes from recovered sawmill processing of coniferous forests. Dry, double-layer installation ensures the greatest thermal inertia and damping of moisture fluctuations.

Design features

The importance of natural materials

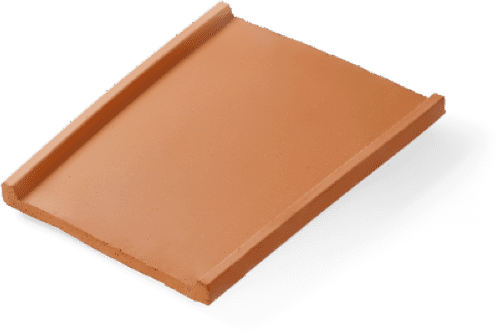

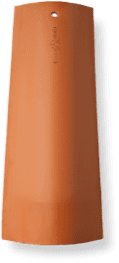

The merits of the ventilated roof are best fulfilled when the ventilated roof is built on a wooden load-bearing structure, with a sloping pitch, with the individual functional layers made of natural and environmentally friendly materials and the covering made of curved brick tiles, roof tiles, laid dry, on a warp also made of wood, and mechanically anchored. Wood is a natural, breathable material and helps stabilize indoor relative humidity. A wooden roof slab allows water vapor and stale ambient air to transmigrate to the outer layers of the roof.

Structural arrangements

Implementation is possible, with appropriate structural arrangements, even in seismic zones. It is important that no vapor barrier is placed at the extrados of the roof slab, but a breathable sheeting that allows the passage of air/steam on the lower face, and is impermeable to water on the upper face, functioning as a windproof and vapor diffusing sheeting.

Wood fiber insulation

Fundamental is the use of wood fiber insulation. In addition to being totally ecological and natural, it is breathable (so it does not block the transmigration of vapor to the upper layers of the roof, nor does it see its insulating power affected by the presence of possible condensed vapor, which cannot form inside it). It has a high density (160 kg/m3, compared with 30 kg/m3 for synthetics and extrusions), which allows good damping of the thermal wave. This means delaying the passage of heat to the rooms below by several hours in summer, and the escape of heat from the dwelling in winter. This type of insulation, in the appropriate thicknesses, together with the inherent advantages of ventilation, provides an unparalleled microclimate and living comfort.

Final layer

A drip-saving sheet with the same characteristics as the windproof sheet should be adopted as the final layer. It does not alter the breathability and thermohygrometric regulation of the roof, and protects, at the same time, against any and accidental water infiltration. Tile roofing has now proven to be the most efficient system for providing shelter from the weather and the disposal of rainwater. Its installation system ensures an excellent seal. The brick material also features good thermal storage capacity, which is to the advantage of the ventilated system. The mechanical anchorage, characteristic of dry laying, ensures the fulfillment of the requirement of resistance to frost and thermal shocks in summer and winter.

Adoption and compliance with these

arrangements ensure:

A greater

durability that

lowers costs and

interventions

maintenance

(anchoring/laying

dry and

ventilation)

Greater ease

in carrying out

any replacements

(anchoring/laying

down dry)

A greater

persistence over

time of the integrity

aesthetics of the mantle

(anchoring/laying in

dry and

ventilation)

Absolute stillness

of the mantle

(anchoring/laying dry)

Working principles

IN WINTER

It allows water vapor, coming from the attic environment, to be disposed of before it condenses on the cold soffit of the roofing membrane, stagnating there and giving rise to possible mold. This provides excellent control of surface and interstitial condensation.

It eliminates any heat given off from attic spaces. It avoids the irregular melting of a possible snowpack, which could result in, both a fall, by sliding, of snow to the ground, with damage to persons or property, and the stagnation of water between the elements of the mantle, as well as a partial absorption of the same, with consequent problems at the lowering of temperatures in the night (frost).

The movement of air in the ventilation chamber is very low, although it still allows the two functions described, so the air behaves as an additional insulating layer, and increases the performance of the one already in place, contributing to the containment of energy consumption (still air is universally recognized as an insulator).

IN SUMMER

It enables the disposal of excess heat in the underlay where the temperature, due to radiation phenomena, can reach as high as 75° C. Quickly disposing of the hot air in the underlay ensures, for those who stay in the rooms below, a cool environment. The heat, in fact, is driven away before it passes to the living spaces, making them unlivable in the summertime. This ensures a fair amount of phase shifting and damping of the heat wave. This, in addition, prevents dangerous stresses related to the phenomenon of thermal shock and ensures good solar radiation resistance of the entire roof.

GENERALLY

It allows the brick mantle to be kept dry at all times because it is constantly aerated. This reduces the risks of mold formation at the extrados of the mantle and damage related to the phenomenon of frost. Dry laying and mechanical anchoring of the brick elements allow for the almost total abatement of these risks.

Ventilation makes it possible to prevent dangerous stresses related to the phenomenon of winter and summer thermal shock. In winter, the problem is related to the large temperature difference between the extrados of the mantle, sometimes below zero, and the intrados at a temperature slightly lower than that of the interior rooms. In summer it depends on very high soffit temperatures, more than twice as high as those outside.

In the absence of ventilation these surges can compromise the roof structure and the membrane itself. Dry-laying systems with mechanical anchoring offer, with regard to the expansion resulting from these phenomena, maximum elasticity and flexibility.